Digital Twins: How Technology Goes Beyond The Basics

Digital Twins: How Technology Goes Beyond The Basics

With the advancement in machine learning technologies and the increased adoption of Big Data, the digital twin concept has become a staple in modern engineering for driving innovation and enhancing systems performance. We offer below a brief guide to this concept.

When we design machines for the connected world, using a traditional engineer’s toolbox may seem totally irrelevant. In this day and age, our technology has become rather complicated, and how we build, scale, and manage our assets and systems has also changed.

Therefore, there is undeniably a need to match up to the prowess of software-driven products fueled by digital disruption.

That is where digital twins enters the picture. They give us a glimpse into what is happening or what can happen with our physical assets in the future.

Looking to invest in building a digital twin? Partner up with top big data companies and machine learning companies on The Manifest.

Digital Twins Definition

Simply put, a digital twin is a digital representation of a physical object or space that spans the lifecycle of the physical object and uses simulation and machine learning to enable informed decision-making.

A digital twin essentially fetches the real-world data about the object as input and delivers predictions or simulations of how that object will behave under a set of conditions.

The idea arose from NASA’s development of full-scale mockups to understand how space capsules might behave in outer space. Digital twins enable a link between the physical and digital worlds, allowing for preemptive problem-solving and improved future planning.

Digital Twins and The Internet of Things (IoT)

IoT technology is becoming more complex day by day. More objects are being developed and coming online, thus generating more data than current systems were designed to handle.

In this regard, digital twins are emerging as a way to get real-time insights into how things and spaces are working. Let us face it, the explosion of IoT sensors is partially responsible for what makes digital twins possible.

And as IoT devices get refined over time, digital twins can be smaller and less complex objects, giving more benefit to companies.

Digital twins can be used for predicting different outcomes based on variable data. This is similar to the simulation often seen in sci-fi films, where a possible scenario comes true in a digital environment.

With the technology, you can also optimize IoT deployment for maximum efficiency using robust digital twin software and data analytics, helping designers identify the best possible way to operate the IoT devices before they are physically deployed.

It makes the installation process more efficient and helps predict future performance and potential failure.

This is especially helpful in industry niches such as manufacturing, where the highly instrumented devices are deployed after the digital twins have simulated how the former performs over a period of time.

Digital Twin vs Simulation

It is important to remember here that a digital twin is not the same as a simulation. A simulation is built purely in digital space and is often used during the product design phase to test how the final product will work - it has no tangible physical counterpart.

A digital twin, however, is designed specifically to mimic an actual object in real-time. Moreover, simulations can be used during the design phase of a product’s lifecycle, trying to predict its functioning in the future.

On the other hand, a digital twin provides all parts of the business insight into how the product or system already in function is performing in real-time.

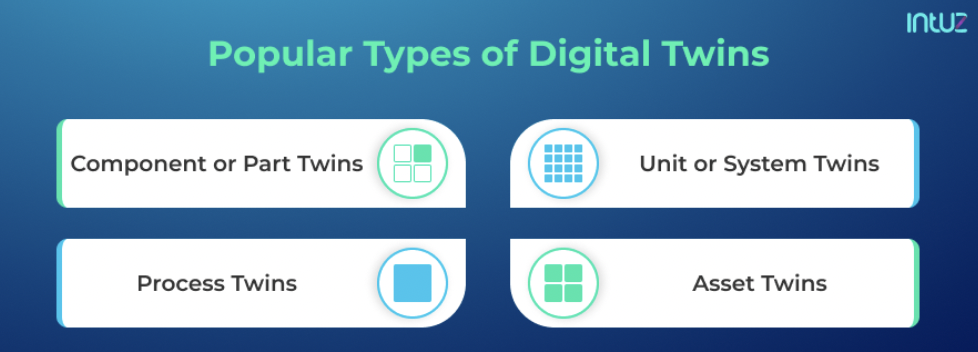

4 Types of Digital Twins

While we will study the use cases of the digital-twin technology in the coming sections, it is essential to first understand the complexity behind digital twins.

What kinds of digital twins are used by engineers today? Let's find out:

- Component or part twins: mirror the minor functioning components

- Process twins: give a top-level view of systems working together, allowing you to determine how an entire factory may operate in a simulated scenario

- Asset twins: mimic two or more components working together, allowing you to study their interactions.

- Unit or system twins: enable you to see how multiple assets function together. This could mean simulating an entire production line - a boon for manufacturers.

Please note that adding more components to the equation increases complexity, especially when you mix and match elements from different manufacturers. Everyone’s intellectual property cannot play nice with your digital twin.

How a Digital Twin Works

Digital twins are constructed by experts in applied mathematics or data science who understand the physics behind the physical object and then design a mathematical model that mimics it in the digital world.

Each twin is designed to receive inputs from sensors that take data from the real-world object to simulate the object in real-time. The inputs are evaluated against contextual data such as prevailing market conditions for the best results.

A digital twin can also serve as a prototype for the physical object, either before the object is built or as a way to refine later versions of the object. It can be as straightforward, or as complex as the scientist wants it to be - naturally, the more data used to build a digital twin, the more exact the simulations will be.

Digital twins let us understand the present and help predict the future. Analysis of data from IoT-connected sensors and devices, combined with other sources of information, assists in product and customer expectations forecasting.

With the wealth of information, businesses can learn faster and put actionable insights into good use. They can break down old notions surrounding product innovation, value creation, and complicated life cycles.

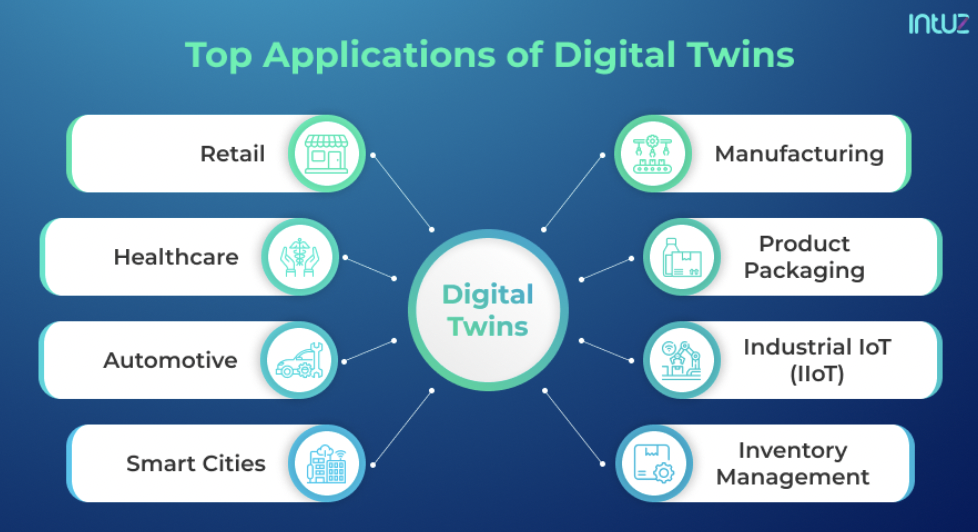

8 Digital Twins Examples

Digital twins are one of the biggest new trends in business and AI. Several industries have already embraced their use, including:

- Retail

- Healthcare and medicine

- Automotive

- Construction

- Manufacturing

- Product packaging

- IoT

- Supply chain

By studying real-time simulations of objects, spaces, or even people, companies can get deeper insights into their current performance and make smarter predictions about the future.

1. Digital Twins in Retail

Digital twins can improve the shopping experience for customers by virtually modeling different fashions, decor items, product uses, and so on.

They can also help optimize store layouts, energy usage, security features, and more - assisting retailers in delivering a more real-life-like experience to customers.

2. Digital Twins in Healthcare and Medicine

Digital twins have significant applications in preventive healthcare, patient monitoring, and customized treatment.

Building a hospital’s digital twin helps healthcare providers to monitor and improve the facility’s operational performance.

Pharma companies can use digital-twin technology to model the physiological characteristics, genome code, and patient lifestyles to develop unique drugs that are more effective than others.

3. Digital Twins in Automotive Manufacturing

Sometimes, a digital twin of an automobile will be made during the design phase to inform execution.

A digital twin of an automobile can serve the following purposes:

- Capture operational efficiency

- Troubleshoot problem areas from afar

- Suggest better safety features

- Improve the usage and comfort of the customer

4. Digital Twins in Construction and Smart Cities

City data from sensors and intelligent networks can help policymakers, and architectural planners see what is working and make decisions accordingly.

It helps optimize public infrastructure, reduce the ecological footprint and offer citizens a better quality of life.

5. Digital Twins in Manufacturing

A digital twin can significantly optimize the manufacturing and maintenance process.

It can support the following manufacturing efforts:

- Identify flaws before production commences

- Undergo stress tests to improve performance

- Reduce throughput times

With digital twins, it is also possible to design various permutations of the product in question.

A digital twin can be used for monitoring products and helping engineers see which products are defective or have lower performance than intended.

6. Digital Twins in Product Packaging

This process can be virtualized and tested for errors before being packaged. Digital twins help logistics companies determine materialistic feasibility.

7. Digital Twins in Industrial IoT (IIoT)

Digital twins and industrial IoT technology are closely intertwined.

Companies can improve current operations and avoid future disruptions and anomalies by using digital twins to monitor and control industrial systems.

8. Digital Twins in Supply Chain Inventory Management

A digital twin of a road network fetches information about the road layout and traffic situation. With that information, you can effectively design the inventory storage locations and distribution routes.

Digital twins and Industry 4.0: Why Does Technology Matter?

In 2017, digital twins were on Gartner’s list of Top 10 Strategic Technology Trends, and for a good reason. Machine learning and IoT have already grown by leaps and bounds, which means implementing digital twins at an industrial scale is easier than ever.

Ushering in a system-based design process allows for a more in-depth understanding of how things work and the opportunity to make improvements preemptively, thus improving user experience while saving valuable resources.

This means organizations can learn much faster, shortening traditional product life cycles and improving the scope for value creation. The digital-twin technology also offers new opportunities for collaboration between data scientists and product experts.

By visualizing real-time situations together, they can use their respective skills to develop more robust solutions than might have come about if they worked separately.

Future of Digital Twins is Bright

Digital-twin technology is set to become “the way to go” across industries. Already some developments could refine the tech further, such as the application of cognitive computing.

As more and more successful pilot projects take off, we will likely see a new industrial revolution - one where ideas and execution happen in tandem for tremendous competitive advantage.

Connect with the best AI companies in the business on The Manifest.